Cherng Ji Single Layer Roofing Roll Forming Machine | CHJ-A-18 Concealed Roof System

Cherng Ji's CHJ-A-18 Single Layer Roofing Roll Forming Machine features automatic hydraulic forming technology with customizable designs for sinusoidal, trapezoidal, and concealed roofing. With 40 years of manufacturing expertise, our machines offer exceptional stability, durability, and easy operation with speeds up to 50M/min for efficient production.

Single Layer Roofing Roll Forming Machine

CHJ-A-18

Concealed Roof Roll Forming Machine

Cherng Ji's Single Layer Roofing Forming Machine features a high-quality automatic hydraulic forming system. It is designed to be easy for customers to operate.

Why Cherng-Ji?

Cherng JI Industrial co., Ltd. has 40 years of roll forming machine manufacturing expertise, customizable to client requirements, our independently developed PLC control system simplifies maintenance and replacement by focusing on faulty module substitution. This precision-oriented approach enhances overall production efficiency and quality. Additionally, thorough incoming inspections ensure supplier components align with drawing specifications, guaranteeing final products meet our customers' exacting standards.

Features

- Highly Customizable: Customized design is available for versatile corrugated sheets, such as sinusoidal / trapezoidal / conceal (clip lock) roofing.

- High Quality: Stability, durability, easy adjustment.

- Multi Speed: Forming speed is optional for normal speed and fly shear.

Machine Specification

- Sheet Thickness: 0.3 ~ 0.7mm

- Forming Speed: 20 ~ 24M/min (Normal Speed), 50M/min. (Fly shear)

- Roller Stations: 18 ~ 26

- Motor Output: 15 ~ 30HP

- Length x Width: 9 ~ 12M x 1.4 ~ 1.8M

- Load Capacity of Uncoiler: 5 ~ 8Tons

Application

- Roof.

- Wall.

- Clapboard.

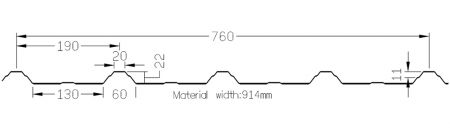

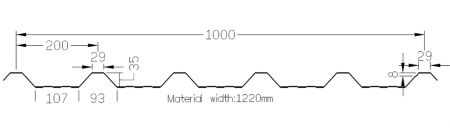

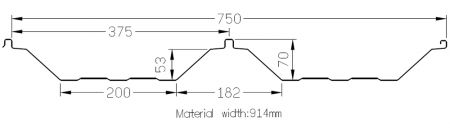

- Forming Sheet of Single Layers Roofing Forming Machine.

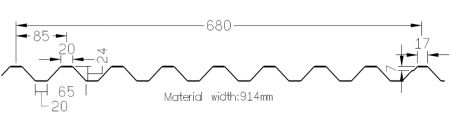

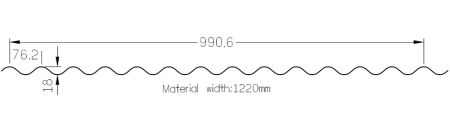

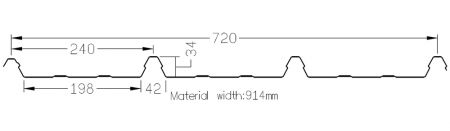

- Forming Sheet of Single Layers Roofing Forming Machine 01.

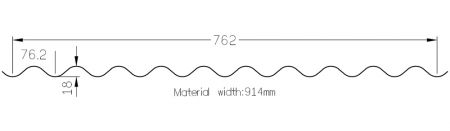

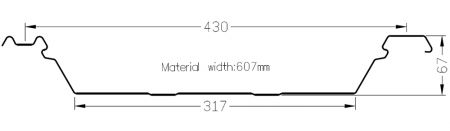

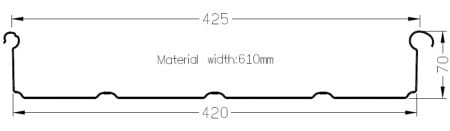

- Forming Sheet of Single Layers Roofing Forming Machine 02.

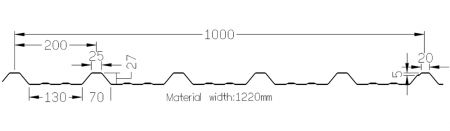

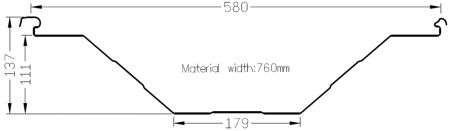

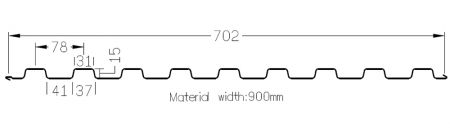

- Forming Sheet of Single Layers Roofing Forming Machine 03.

- Sample Section

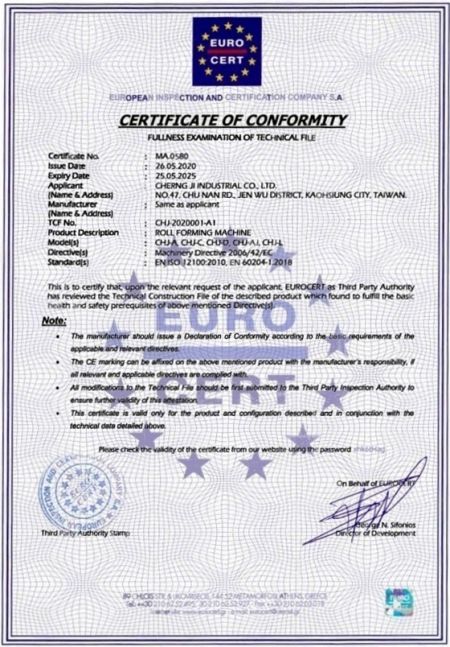

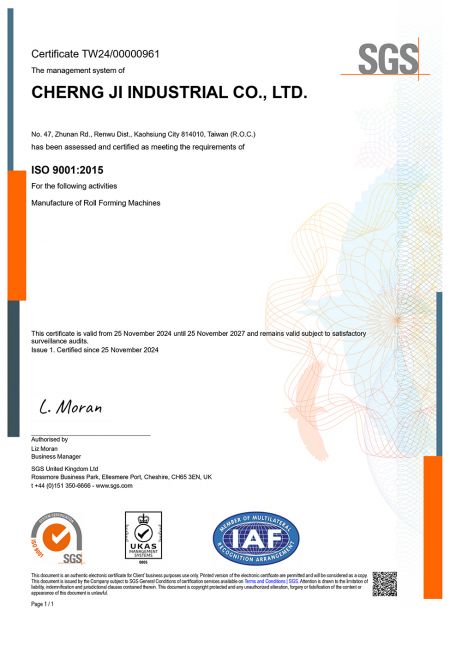

- Certificate

- Video

How Does Advanced PLC Control Impact Your Metal Forming Operation's Efficiency?

Cherng Ji's independently developed PLC control system revolutionizes maintenance procedures by focusing on modular component replacement rather than complex troubleshooting. This approach significantly reduces downtime, minimizes maintenance costs, and extends machine lifespan. For metal forming processors, this translates to higher operational efficiency and improved profitability. Schedule a demonstration to see how our advanced control systems can transform your production capabilities.

Engineered with precision and durability in mind, the CHJ-A-18 incorporates Cherng Ji's independently developed PLC control system that simplifies maintenance through modular design, allowing for quick troubleshooting and component replacement. The machine's robust construction ensures exceptional stability and longevity while maintaining easy adjustability for different production requirements. With customizable configurations featuring 18-26 roller stations, motor outputs of 15-30HP, and uncoiler load capacities of 5-8 tons, this roll forming solution delivers the versatility and reliability demanded by roofing, wall cladding, and architectural panel manufacturers worldwide.