Cherng Ji PU Sandwich Panel Line | Industrial Insulation Solutions | CHJ-A-38

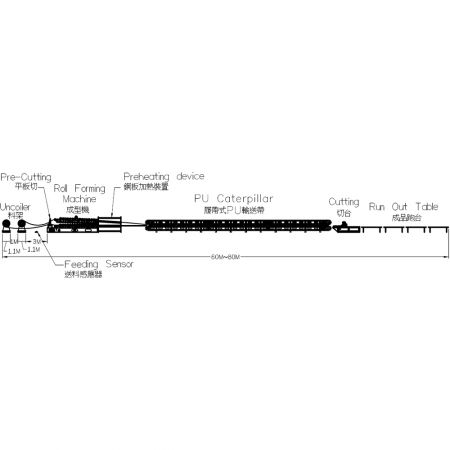

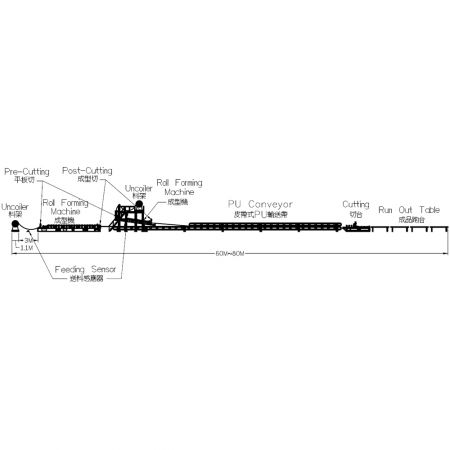

Cherng Ji's CHJ-A-38 PU Sandwich Panel Production Line offers superior thermal insulation for cold storage, cleanrooms, and pharmaceutical facilities. With 40 years of expertise, our customizable caterpillar-style lines produce panels of various thicknesses (50-150mm) and widths. Advanced PLC control system ensures precision manufacturing with simplified maintenance.

Glazed Tile Roofing Roll Forming Machine

CHJ-A-38

Cherng Ji Industrial Co., Ltd. has two types (Track / Belt) of sandwich panel production lines, both of which are caterpillar-style lines that can produce sandwich panels with various thicknesses and widths. These panels are also excellent for insulating against heat and cold.

Why Cherng-Ji?

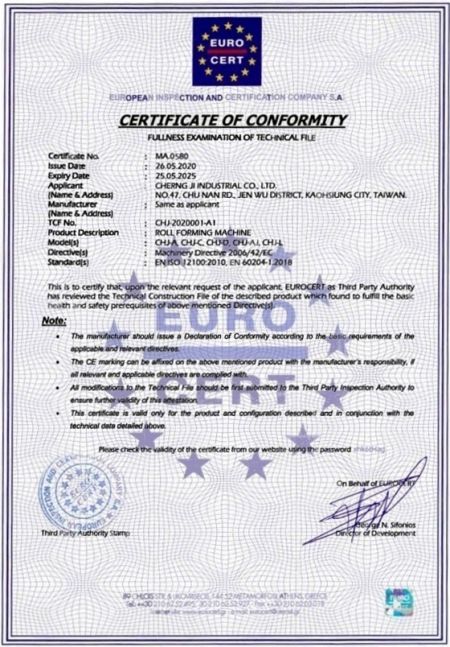

Cherng JI Industrial co., Ltd. has 40 years of roll forming machine manufacturing expertise, customizable to client requirements, our independently developed PLC control system simplifies maintenance and replacement by focusing on faulty module substitution. This precision-oriented approach enhances overall production efficiency and quality. Additionally, thorough incoming inspections ensure supplier components align with drawing specifications, guaranteeing final products meet our customers' exacting standards.

Features

- Continuous / Discontinues: Continuous / Discontinues (Bridged type) production for sandwich panels.

- Heat & Cold insulation: Best choice for heat & cold insulation even soundproof.

- Highly Customizable: Our products can be highly customized to meet customers' needs.

- Various Application: Frozen / freezing storage, clean room, laboratory, food / pharmaceutical / sanitation arena.

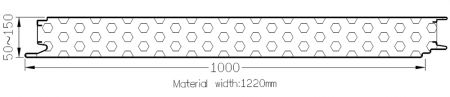

Machine Specification

- Sheet Thickness: 0.3 ~ 0.7mm

- Forming Speed: 1 ~ 6M/min

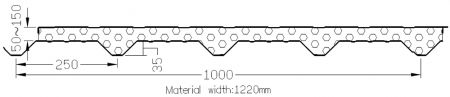

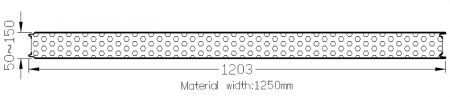

- PU Thickness: 50 ~ 150mm

- Length x Width: 60M x 5M

Application

- Frozen / Freezing Storage.

- Clean room.

- Laboratory.

- Food / Pharmaceutical / Sanitation Arena.

- Sample Section

- Certificate

- Video

Why Is Customization Capability Critical for Pharmaceutical Facility Insulation Systems?

Pharmaceutical facilities face unique challenges requiring precisely tailored insulation solutions. Cherng Ji's highly customizable PU sandwich panel production line addresses these needs by allowing specification of exact panel dimensions, thermal ratings, surface materials, and joint systems. This customization ensures compliance with GMP requirements, accommodates specialized equipment installation, and creates optimal conditions for different production zones within the same facility. Our 40 years of experience working with pharmaceutical contractors worldwide has refined our understanding of the critical parameters that impact validation processes and regulatory compliance.

Backed by Cherng Ji's 40 years of roll forming expertise, the CHJ-A-38 features our proprietary PLC control system that simplifies maintenance through modular design—allowing for quick identification and replacement of faulty components. The system operates at speeds of 1-6 meters per minute with precision sheet thickness handling of 0.3-0.7mm, ensuring consistent quality across production runs. Our rigorous quality control process includes thorough component inspections that guarantee all panels meet international standards for thermal efficiency, structural integrity, and long-term performance in demanding industrial applications.