Cherng Ji Tapered Roofing Roll Forming Machine | Standing Seam Roof System

Cherng Ji's CHJ-AJ-02 Tapered Roofing Roll Forming Machine features fully computerized width adjustment, producing both rectangular and tapered sheets without roller changes. Ideal for airports, stadiums, and train stations with 40 years of manufacturing excellence. Request a quote today!

Tapered Roofing Roll Forming Machine

CHJ-AJ-02

Standing Seam Roof Machine

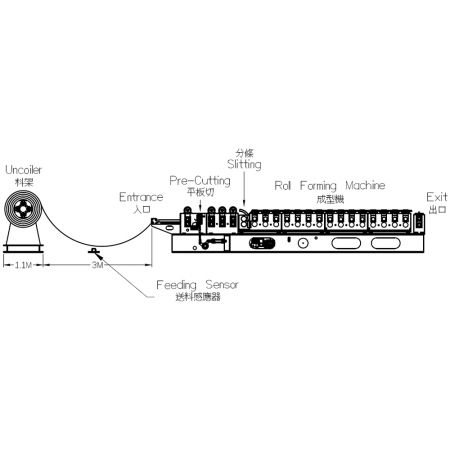

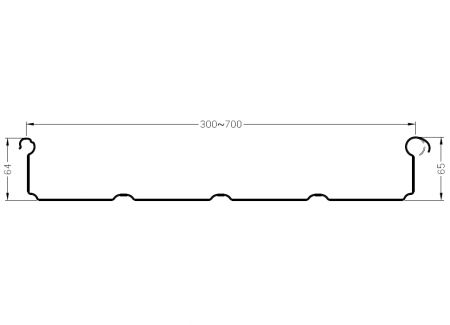

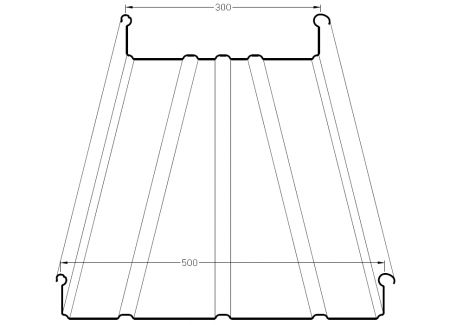

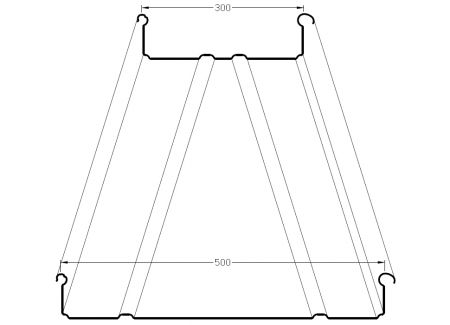

Cherng Ji's Tapered Roofing Roll Forming Machine is fully computerized and specially designed for various widths. It can produce two kinds of products: one is rectangular, and the other is tapered sheet. All you need to do is input the width or the sizes of both ends, and the computer will adjust all rollers to the right position. The adjustment time is around 2-3 minutes without changing rollers.

Why Cherng-Ji?

Cherng JI Industrial co., Ltd. has 40 years of roll forming machine manufacturing expertise, customizable to client requirements, our independently developed PLC control system simplifies maintenance and replacement by focusing on faulty module substitution. This precision-oriented approach enhances overall production efficiency and quality. Additionally, thorough incoming inspections ensure supplier components align with drawing specifications, guaranteeing final products meet our customers' exacting standards.

Features

2 Ways Automatically Produced

● By the PLC, tapered sheets (both ends=different widths) can be produced automatically, roller adjust along with the section width in production automatically.

● By the PLC, sheets of different widths (both ends=same width) can be produced automatically.

Machine Specification

- Sheet Thickness: 0.6 ~ 1.0mm

- Forming Speed: 10 ~ 20M/min

- Roller Stations: 18 ~ 20

- Motor Output: 20/HP

- Length x Width: 8M x 2M

- Load Capacity of Uncoiler: 5/Tons

Application

- Roofing in Airport.

- Train / Metro Station.

- Stadium.

- Exhibition Venue.

- Sample Section

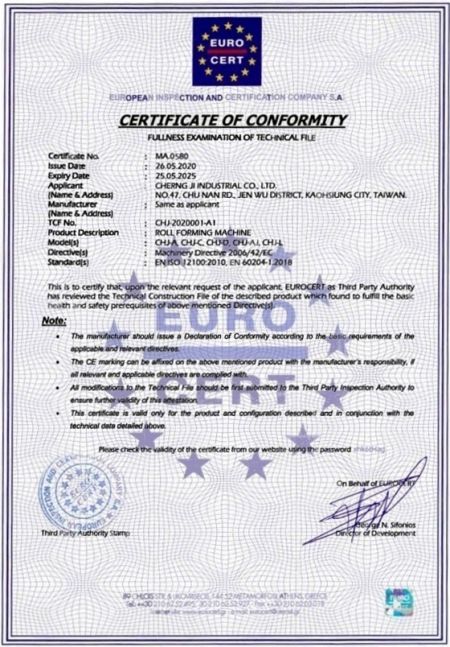

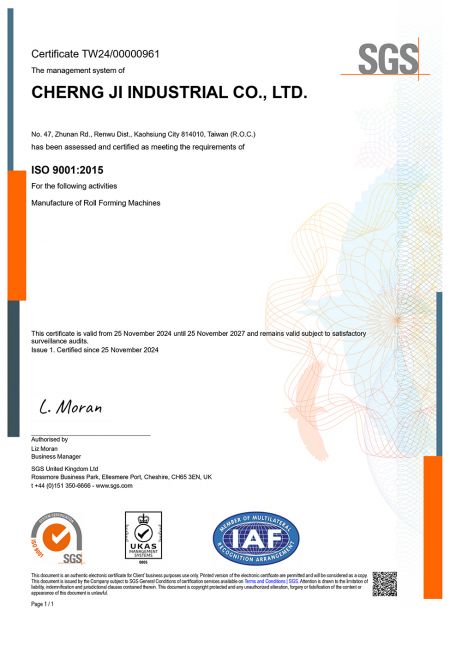

- Certificate

- Video

How does production capacity impact airport construction schedules and budgets?

Airport infrastructure projects operate under strict deadlines where construction delays directly impact operational timelines and financial projections. Our tapered roofing roll forming machine's 10-20m/min production speed and 5-ton uncoiler capacity ensure continuous high-volume output of precision metal panels required for expansive terminal roofing. By bringing this production capability on-site, airport developers can eliminate long lead times for custom panels, adapt to design modifications in real-time, and maintain greater control over material quality—ultimately keeping large-scale airport construction projects on schedule and within budget constraints.

Engineered with 40 years of manufacturing expertise, the CHJ-AJ-02 delivers exceptional performance specifications including processing capabilities for sheet thickness from 0.6-1.0mm, production speeds of 10-20 meters per minute, and 18-20 roller stations for optimal forming quality. The robust 20HP motor and 5-ton uncoiler capacity ensure reliable operation in demanding industrial environments. Every machine undergoes rigorous quality control through our comprehensive incoming inspection protocols, guaranteeing that all components meet exact specifications before assembly. CE-certified and ISO 9001 compliant, this standing seam roof machine represents Cherng Ji's commitment to delivering customizable, high-efficiency solutions for sophisticated architectural metal forming applications worldwide.