Cherng Ji Adjustable Stud & Track Roll Forming Machine | PLC Control System

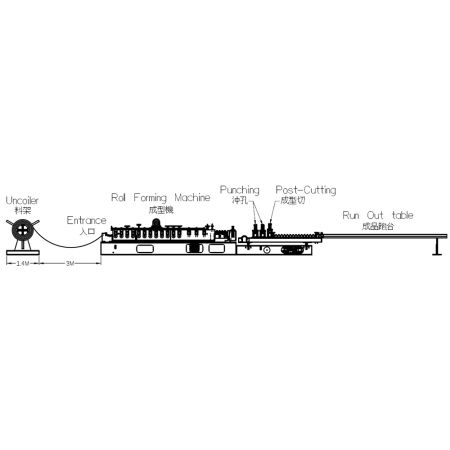

Cherng Ji's Adjustable Stud & Track Roll Forming Machine offers PLC control with 5-minute roller adjustment, integrated punching system, and fly shear capability. Featuring 0.6-1.5mm sheet thickness capacity and 20-50M/min forming speed. Backed by 40 years of manufacturing expertise. Request a quote today!

Adjustable Stud & Track Roll Forming Machine

CHJ-AJ-04

Metal Stud Track Roll Forming Machine

Cherng Ji's Adjustable Stud and Track Roll Forming Machine is easy to control through a PLC, providing outstanding flexibility for users when they are using the machine to produce merchandise.

When an operator wants to adjust the rollers, they just need to press a button on the PLC and wait for 5 minutes. This allows the position of the rollers to transfer to another configuration to produce different products.

Additionally, our machine offers high productivity as it can be done by integrating an online punching system and a fly shear as well. This not only helps the user have an efficient production process but also reduces costs.

Why Cherng-Ji?

Cherng JI Industrial co., Ltd. has 40 years of roll forming machine manufacturing expertise, customizable to client requirements, our independently developed PLC control system simplifies maintenance and replacement by focusing on faulty module substitution. This precision-oriented approach enhances overall production efficiency and quality. Additionally, thorough incoming inspections ensure supplier components align with drawing specifications, guaranteeing final products meet our customers' exacting standards.

Features

- Easy Control and Flexibility: Controlled by PLC, providing outstanding flexibility.

- Quick Adjust: It only takes within 5 min. for automatic roller adjustment.

- Efficiency Produce: High productivity can be done by integrating on-line punching system and fly shear as well.

Machine Specification

- Sheet Thickness: 0.6 ~ 1.5mm

- Forming Speed: 20 ~ 50M/min

- Roller Stations: 14 ~ 16

- Motor Output: 20 ~ 30HP

- Length x Width: 9 ~ 11M x 1.5M

- Load Capacity of Un-Coiler: 3Tons

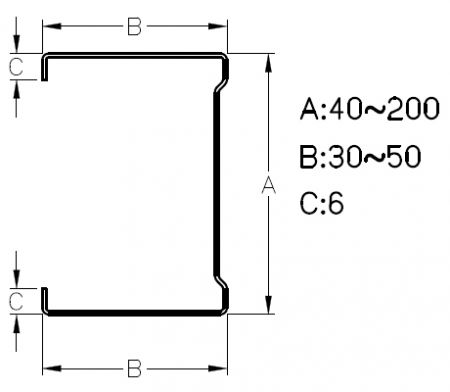

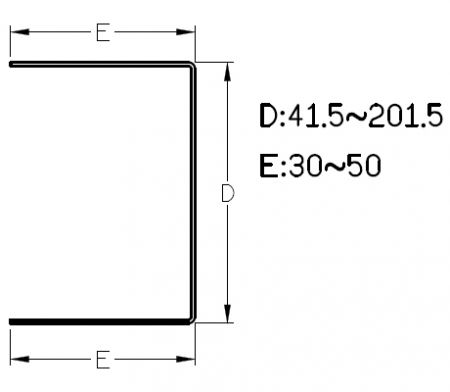

- Sample Section

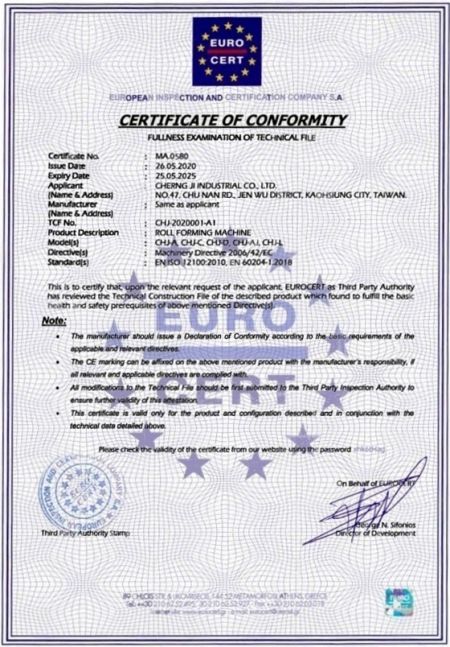

- Certificate

- Video

-

Cherng Ji Industrial Co., Ltd commercial film.: This video showcased why Cherng Ji can produce high-quality roll forming machines, including robust research and development, reliable processes, and excellent service. We continuously improve to provide our customers with the best products.

Adjustable Stud & Track Roll Forming Machine

How Can Rapid Roller Adjustment Transform Your Metal Stud Production Efficiency?

Our Adjustable Stud & Track Roll Forming Machine enables complete profile changes in just 5 minutes with simple PLC button operation. This revolutionary feature eliminates lengthy manual adjustments, allowing you to run multiple product lines with a single machine and respond quickly to varying customer orders. Calculate how much production time you could save monthly with our ROI calculator or request a personalized efficiency assessment.

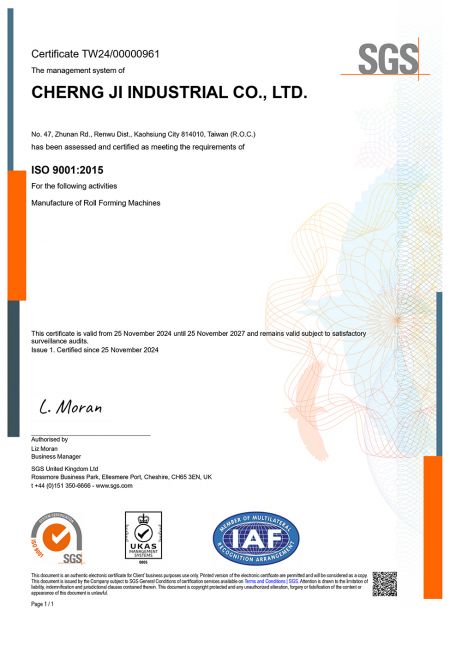

Engineered for seamless integration with online punching systems and fly shear mechanisms, the CHJ-AJ-04 offers a complete production solution that enhances efficiency while reducing operational costs. The robust design includes 14-16 roller stations powered by a 20-30HP motor, ensuring precise forming and consistent quality across various metal stud and track profiles. Each machine undergoes rigorous quality control and is backed by Cherng Ji's comprehensive after-sales service, making it the preferred choice for construction material manufacturers seeking reliable, high-performance equipment with CE certification and ISO 9001 quality assurance.